Service Overview

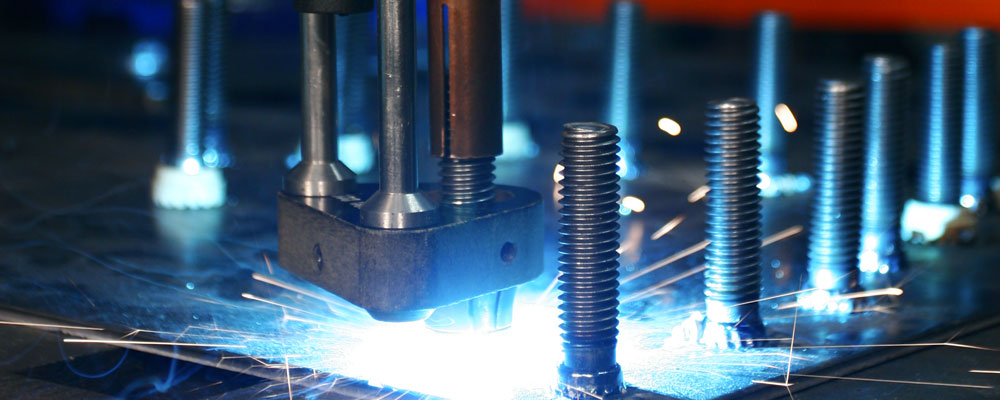

Stud welding is a process of arc pressure welding, where an arc of lightning speed is used to fasten a metal stud or pin to its workpiece. After the welding time has elapsed, the current is switched off, thus allowing the stud to melt and position itself securely when cool.As no holes are punched in the sheet, the workpiece is leak proof and not weakened easily and corrosion problems are also minimized.

This incisive joining technique is used in multiple fields of various industries. Varying from objects that are used on daily basis to building composite infrastructures in the construction field.

TYPES OF WELDING

Stud welding with ceramic ferrule

The primary purpose of the ceramic ferrule is to shield the stud from the air during the welding process and prevent porosity. This process uses studs of an approximate diameter of 3 to 25 mm, welding current up to 3.000 A and welding times up to 3.000 ms.

The ferrule is first placed on the workpiece while the stud is positioned in the chuck of a stud welding gun. As soon as the trigger is pushed, the current flows through the gun allowing the stud to lodge itself in the safety of the ferrule, creating a very effective bond between the metal and workpiece. The ferrule once cooled needs to be chipped in the end to complete the weld.

Stud welding of this nature is widely used in manufacturing operations for connecting various components, support structures, assemblies, and composite construction.

ADVANTAGES

Welding is a growing in-demand trade with limitless possibilities

- Welding can be performed using various energy sources that that fit open air, underwater, and even space settings.

- Produces stronger joints than brazing and soldering.

- High productivity through extremely short welding time.

- Corrosion problems are also minimized.

- . Being able to join thin and thick sections of metal (depending on process type)

- Easy to operate for personnel trained on the job

Site Surveys

On request Engineers will be sent.